Purlins

Overview

Overview

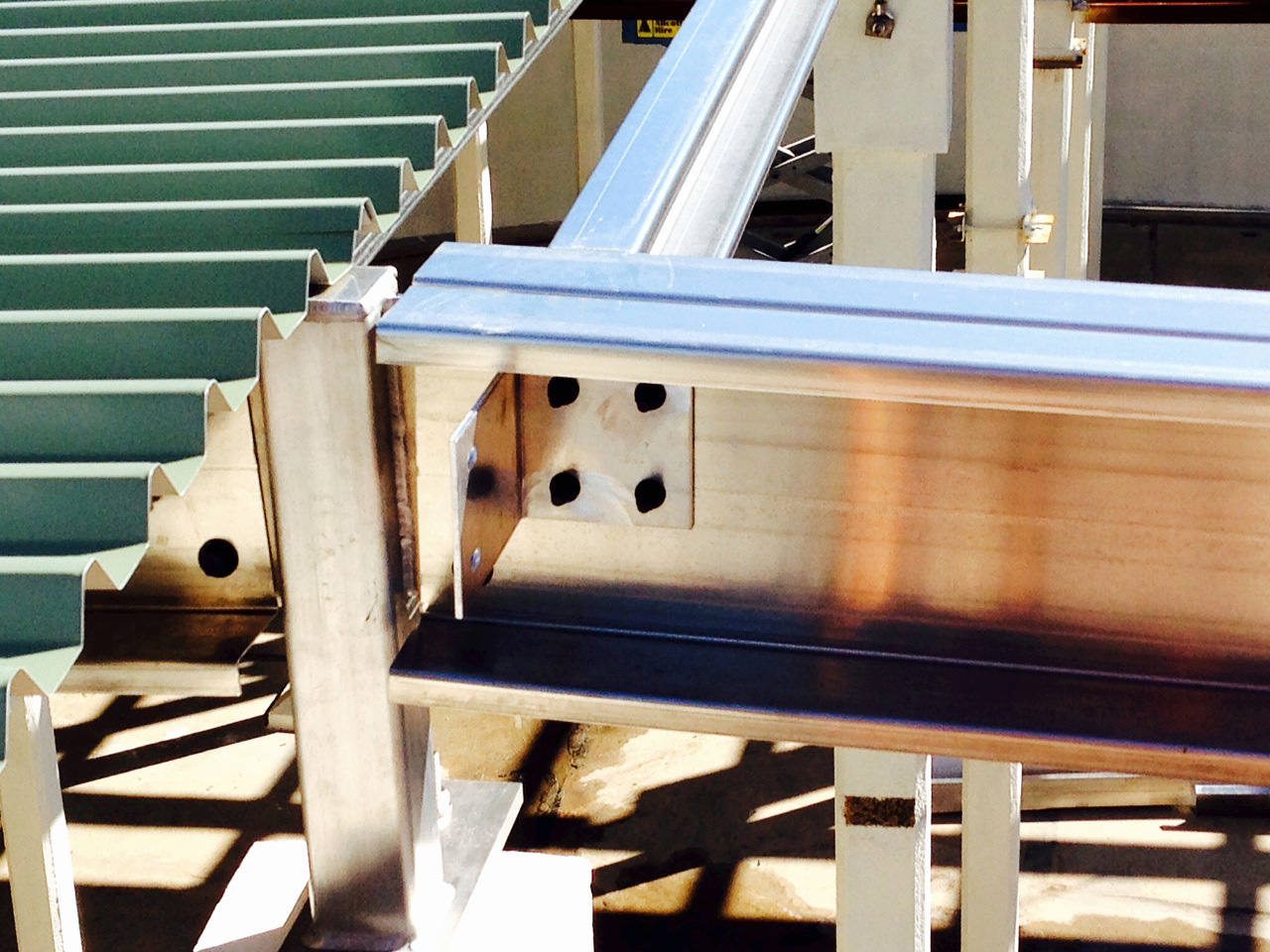

Permalite® purlins and girts are commonly used in commercial, industrial and rural buildings, reservoirs and severe marine environments. Coastal bulk material handling plants such as coal, sugar and grain loaders, as well as water storage reservoirs, agricultural storage sheds, power stations etc all have high corrosion risk structures. Now architects, builders and engineers can extend the application of aluminium beyond the external cladding and windows to include the support framing as well.

Permalite® have created a range of roll formed aluminium sections encompassing traditional C and Z sections, as well as downturn lip versions of these shapes across the entire range. Some of the advantages of roll formed purlins and girts versus extruded sections are:

- Sections maybe punched and cut to length during the roll forming process, thus eliminating high post processing costs.

- There is some flexibility in section sizes and smaller production runs are possible eliminating costly waste.

- Lead times are significantly reduced ensuring smoother project completions

Although the Permalite® purlins and girts sections have been designed for this specific application, due to their versatile shape there is a vast range of other applications where these sections are equally useful and commonly used. Some of these other applications are:

- Structural frame of small and medium sized buildings

- Floor joists

- Rafters and beams

- Posts

Other special shapes may be produced using extrusion versatility to either omit the flange lips by using thicker flanges, using bulb ends or other special shapes. A variety of aluminium purlin sections and dedicated accessories are available and can be cut to length and pre-punched if required. We can supply a range of standard C and Z sections and are happy to assist you with design advice in regards to correct product choice.

For larger projects we are also capable of supplying tailored solutions to suit your project requirements.

Specification

Specification

Material Specification

Our standard Cee and Zed purlin shapes are all roll-formed in a well proven marine grade structural aluminium alloy 5052 H36 which combines the properties of high strength with excellent resistance to atmospheric corrosion and is particularly suited to marine structures and water reservoir roofing applications.

Mechanical properties according to AS/NZS1664.1:1997.

- Yield 179MPa

- Ultimate Tensile Strength 255MPa

- Elastic Modulus (for deflection calculations) 69.3GPa

Other tempers would be recommended if members require subsequent bending for curved structures.

Fasteners

Grade 316 SS A4 70 Stainless Steel bolts, nuts and washers (M12 and M16 x 45mm) are recommended. Permalite® offers 316 SS bolts with a Fluoropolymer coating to provide electrolytic isolation.

In highly corrosive environments additional isolation is recommended via the use of PVC or similar isolation washers.

This combination will give the best results in environments in which aluminium purlins are most suited.

Brochures

Brochures

Permalite Aluminium Rollformed Purlin Solutions Manual

Download Now (8.59 MB)

Availability

Availability

Available Lengths

Permalite® Purlins are available custom-cut in any transportable length, however there are some limitations. Minimum length is 1,800 mm and maximum length is 16,000 mm. Lengths <1,800mm will be combined and come with ‘part cuts’ for easy separation and identification on site. Length tolerance for all sections is +/- 5mm.

Non-standard Purlin options are available on special projects only and will be subject to minimum order quantities and extended lead times.

The non-standard purlin options include:

• variation of material specifications

• variation of profile dimensions

• variation of material thickness

These options could be considered to tailor a profile specifically for project needs. The C profile is also available with unequal flanges to allow boxing of members.

Accessories

There is a range of accessories available for use with our purlins. These accessories are an integral part of the unique Permalite® purlin and girt system.

Purlin bolts with PVC Washers/Grommet Washer

Structural Grade A4-70 316 Stainless Steel (M12 x 40mm, M16 x 45mm) with washers at both the head and nut shall be used for all types of connections described in this manual as required by AS/ NZS 1664:1:1997. Fluoro-polymer coated bolts, nuts and washers are recommended to provide electrical isolation between stainless steel and aluminium. Rigid PVC washers under bolt heads or washers are recommended to reduce thermal movement, noise and any risk of crevice corrosion in highly corrosive environments.

Purlin trimming brackets

A variety of aluminium brackets are available for trimming around wall and roof penetrations such as doors, windows and services.These brackets are for lightly loaded applications, not for highly loaded structural connections.

For special projects, please contact us, we would be happy to consult and quote as required.

The major benefits of aluminium Purlins are their corrosion resistance, ease of handling and crane hire savings in difficult situations.