Floor Planks

Overview

Overview

Many areas of Australia experience very adverse conditions such as marine or severe industrial corrosive environments. In these situations, building structures can benefit from the corrosion resistance and light weight features of extruded aluminium structural systems.

Coastal bulk material handling plants such as coal, sugar and grain loaders, as well as water storage reservoirs, agricultural storage sheds, power stations etc which all have high corrosion risk structures.

Now architects, builders and engineers can extend the application of aluminium beyond the external cladding and windows to include the support framing and flooring as well.

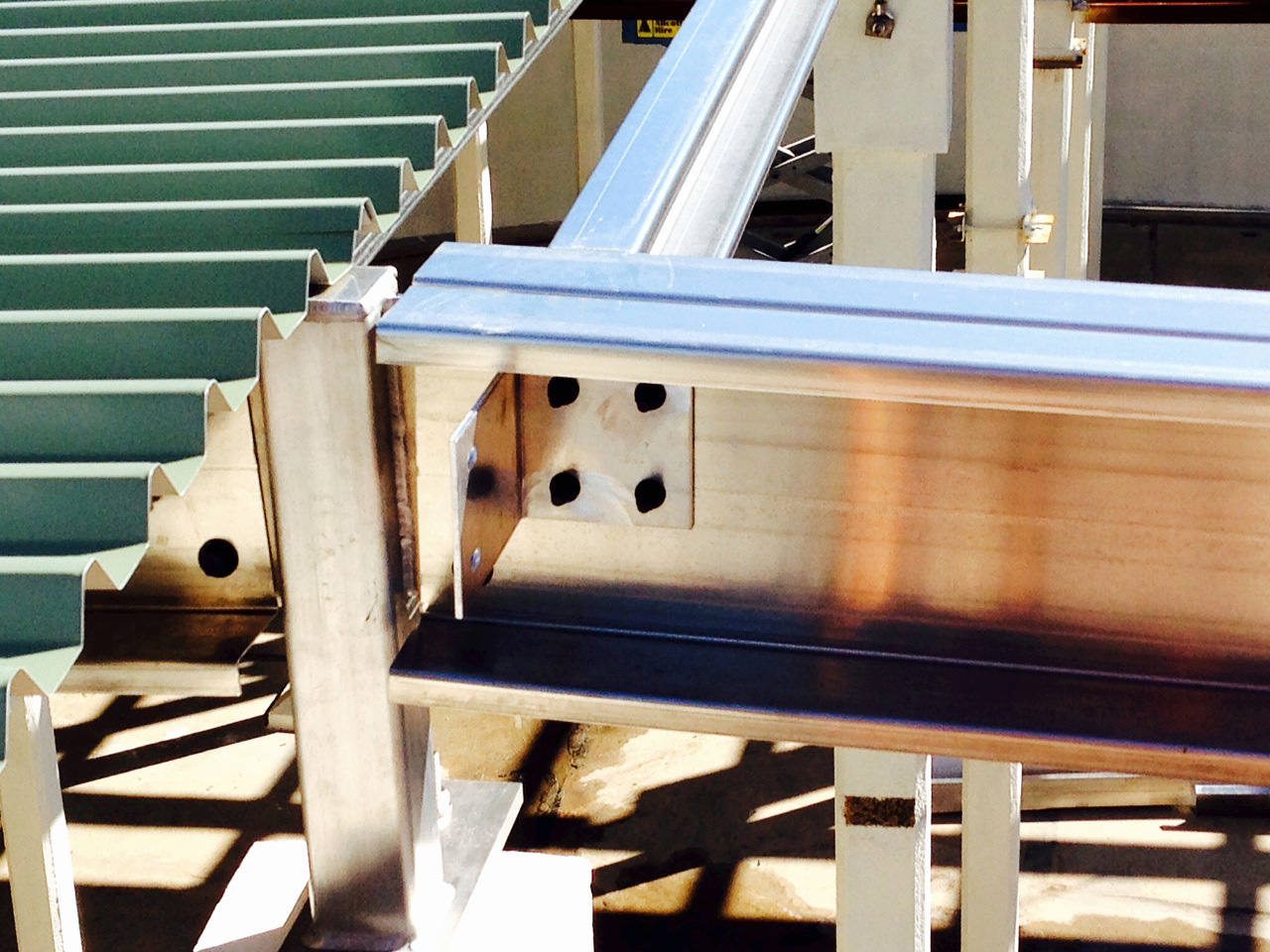

Our floor plank design provides an industrial floor system capable of carrying 5kpa traffic loads and is especially useful in containing dust particles and preventing falling objects from contaminating environmentally sensitive areas below.

Incorporated into our plank design is a left and right, fully extruded, kick-rail which saves 4 meters of full welding per lineal meter and totally eliminates any distortion due to the welding process.

A diverse range of aluminium floor plank sections and dedicated accessories are available from Permalite® and can be cut to length knurled and milled if required.

In addition to the standard floor plank shapes, we can supply many other structural aluminium alloy extrusions as well as aluminium mesh and plate for your project.

Specification

Specification

Material Specification

All our floor plank shapes are all produced in a well proven structural aluminium alloy 6060 T5 which combines the properties of high strength with excellent resistance to atmospheric corrosion and is particularly suited to marine structures and other corrosive environments.

Typical average mechanical properties of this alloy across various shapes are:

- Alloy 6060

- Temper T5

- Ultimate Tensile Strength(UTS) 152 MPA

- Tensile Yield Strength 110MPA

- Shear Yield Strength 62MPA

- Modulus of Elasticity 69MPA

Floor Plank Range

The range consists of 3 plank types as well as ancillary component for fixings. All planks have a nominal width and height of 250mm x 75mm (cover width 237mm) and a web thickness of 3mm. The planks are connected via a tongue and groove arrangement, providing load sharing as well as the ability to seal the floor system to capture dust and or liquids.

Fixings

Fixings are recommended to be of corrosion resistant materials such as aluminium alloy or 304/316 stainless steel. This combination will give the best results in environments in which aluminium floor planks are used.

The system provides time-tested security through the use of stainless steel screw fixings to floor frame and aluminium rivets for plank to plank connections. Allowance for expansion of floor planks is recommended as thermal movements of approximately 0.25mm per metre per 10º C is often encountered.

Nylon washers under screw heads are recommended to reduce thermal movement, noise and any risk of crevice corrosion. The use of PVC

isolation tapes or equivalent, e.g. Tremco ALTA 300-40 Isolation tape, to the full width of the flange should be used to separate dissimilar materials.

Brochures

Brochures

Permalite Aluminium Industrial Floor Plank Solutions

Download Now (1.91 MB)

Availability

Availability

Available Lengths

Permalite® floor plans are available custom cut to most transportable lengths, however there are some limitations.

For normal deliveries nominal lengths should not exceed 12,000mm. Lengths greater than 12,000mm require special transportation and on-site handling facilities. Please check local laws regarding permits and requirements for oversize deliveries.

Lengths greater than 19,500mm require a special transportation permit and non-containerised shipment. Length tolerance for all sections is ±5mm.

For minimum lengths, and lengths over 12,000mm, please contact us.

The Permalite® floor plank design provides an fully extruded industrial floor system capable of carrying 5kpa traffic loads.